Nestled in south-east London, in an arch underneath rail tracks, is the creative home of Insley & Nash. Inside, the fashion duo specialises in printing techniques that many printers will not even consider undertaking.

That passion for their craft is precisely what drove Gavin Insley and Mika Nash to form their business and studio – to provide a creative service for designers who had great ideas and who needed short runs of high-quality printing and dyeing.

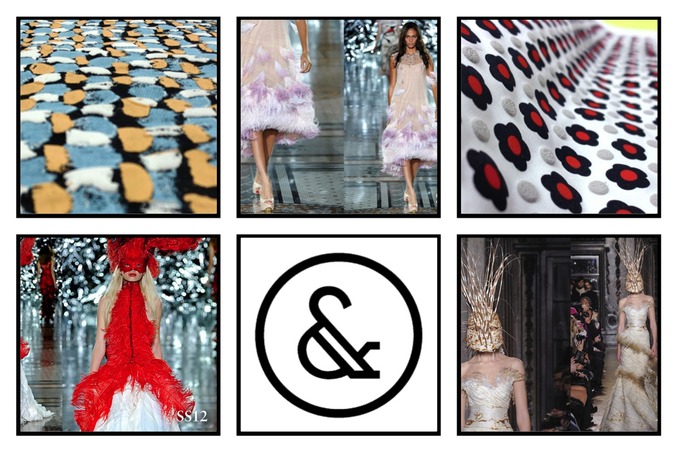

The studio has worked with a broad range of clients from the fashion, textile, interiors, film and TV industries. As well as their high-end bespoke screen printing, the creative duo launched their partner brand &Digital – a digital textile service available to order online.

Insley & Nash specialise in flat-bed screen printing in small quantities and often have well-known British brands and designers come to them with a vision that they are looking to create. It may either be a sample piece or a one-off collection commission – yet with both of their fashion, printing, and design know-how they pride themselves in continually creating exciting new techniques and processes for all of their clients.

We met Gavin and Mika in their studio where they showed us around their printing facilities and told us about their clients and business adventures in the near future.

What are your backgrounds?

Mika: We both studied Fashion at Ravensbourne – Gav was the year above me. The college had the most amazing print facilities and it would have been a waste to not use those to our advantage. I worked with Zandra Rhodes afterwards. I started as an intern and worked my way up to be the head screen printer.

Gav: I specialised in Print and worked as a technician at Ravensbourne after I graduated and then went on to work at a trend forecasting company until we decided to start our company.

How did you fund your business?

Mika: It was savings. We scrimped and saved and we had no government funding whatsoever. It was during the recession so banks were not handing out loans and we did not qualify for anything, unfortunately.

Gav: The most we could get was a little bit of advice from Greenwich Council – our local council, they offered this scheme called the South East Enterprise which I don’t think exists anymore, we luckily got given an incredible business advisor who we are still in contact with today.

Was it a slow process?

Mika: Incredibly slow! We were both fortunate that we both could work part-time elsewhere. After a few months, we decided to quit our jobs. We then moved to a tiny little art studio that could only fit one printing table. We were there for about 18 months and then moved to a shared studio.

How did you find your studios?

Gav: The first studio we rented was through an ASC – a charity organisation that supports artists; since at the time we were going down the art route, we fit their criteria. It was a reasonable amount of money for a studio, but at the time it was the most expensive thing we had ever spent money on.

Is your client base full of a wide range of people and businesses?

Gav: It is across the board really, we work with students all the way through to large multinational companies. The larger companies are not looking to order thousands of metres – they come to us for smaller, experimental projects, and then they may take it elsewhere, or it might just be a press piece for them.

How do your clients find out about you, is it through word of mouth?

Mika: It started off that way when we first started and we had our tiny studio. Now we market ourselves. We are actually going to be at Meet The Manufacturer so we are excited about the potential of meeting new clients.

Do you have a typical client?

Gav: Our clients are varied. We are working with an accessories brand at the moment called Everything Eleven, which will soon be stocked at Net-A-Porter, which is huge for her and for us. We are also in the process of making a product for Disney, which again is extremely exciting. Also, we are working with Agi & Sam with whom we have worked previously. We created their reflective prints last season all on wool so we are sampling for them now and finishing off their production.

We’ve just finished working on student projects. We have a good link with Kingston University, where we often go to talk and as a result end up helping many students with their final projects. It is great to work with students because we get to work on more unusual projects with them. They are never going to be looking at hundreds of metres, so we know that we can concentrate on the smaller quantities.

And as we offer everything from developing an artwork from scratch to just putting things into repeat or even just scaling up little jobs. We occasionally work on TV and advertising projects and usually, they are the ones that need the whole service. We have a campaign coming up for Pepsi for the World Cup, for the Nigerian football team – we printed their football tops.

You are known for screen printing but now also offer digital print?

Gav: Yes, we have had the digital printer up and running since October so it is a really new service for us. It is very easy for people to use, which is what we wanted. We have set up a new website and you can order through the website and you don’t even need to speak to us if you wish. You can order what you want, pay for it and five days later it appears at their door. That obviously appeals to a wider audience than screen printing which is bespoke and a more expensive process. It is coming to about 50/50 of the business at the moment but I believe digital will take over in time.

What is your favourite part of the business?

Mika: For me personally it changes a lot, there are parts of running a business that is enjoyable, and there are parts that are horrible. Sometimes you can get a real kick out of getting the accounts and sometimes the printing and dyeing is a real pain….

Gav: I would agree, I mainly concentrate on the digital side of the company so I don’t really get my hands dirty anymore, which has changed because I used to come home covered in dye and stinking of chemicals. I find the running of the business extremely rewarding, which is the first time I would say we have been able to feel like this in the three years without feeling too stressed.

If you could go back and give yourself advice, what would it be?

Mika: I would say learn from the beginning how to best work as a team and don’t get too emotionally attached to the work. Set procedures in place early on and be tough especially where payments are concerned. We have had instances where small clients have criticised our work in order to get out of paying for it, despite us having spent hours and days perfecting it. But that is sadly part of the industry and we have learned from it, and are a stronger business now because of it.

What are your plans for the future?

Mika: We have a range of short-term and long-term goals. They keep us on track of where we are going and what we aim to achieve. We want to make more of a brand of ourselves. We are now the newest textile company in the UK and we want to promote and use that to our advantage.

If you wish to find out more about Insley & Nash please visit their website.

There are so many incredible interviews of manufacturers in our Meet The Maker series. Right from China to India, we have a bucket load of people waiting to inspire you.