Cutting fabric for production is a skill seasoned professionals know about and use as a way to make savings. Scaling up from sampling to production is a huge leap in regards to fabric and trimmings consumption.

The fabric you use represents up to 80% of the total garment cost and is the most important component on your costings sheet. To ensure successful growth in your business, when cutting fabric for production, fabric yield must be properly monitored. Fabric consumption costs must be noted during the sampling phase, so create a simple fabric costings sheet that lists the following: Fabric type, fabric width, fabric supplier and fabric yield. This sheet can then be used to calculate fabric consumption for production purposes.

Producing a moderately sized sample collection of eight to fifteen items will appear to cost you more than it would if you were producing larger quantities of each style. The reason being that fabrics and trims, when bought in bulk will be cheaper than when purchased in single units. All wholesale companies offer prices based on the purchase of 1-5 meters, 5-10 meters and so on.

The lower the number, the more expensive the fabric is per meter.

Points to Consider for Optimum Fabric Consumption

- The weight (GSM) of your fabric will determine the lay height when your production garments are cut out.

- Prior to getting your patterns made, source your materials and determine the Fabric Width. This information is important for the pattern cutter to develop patterns that maximize the fabric width which will reduce waste and save you money. Fabric widths are usually 45’’, 50’’ and 60’’.

- Knitted fabrics are, generally, circular and narrower 28’’, 32’’, and 34’’. They’re usually used for underwear where the pattern pieces are narrower to accommodate the stretch in the fabric.

- Open-width knitted fabrics are produced by cutting one side of the circular knitted fabric and laying it flat. The fabric width is then optimized when the patterns are laid.

- The Grain Line Orientation is usually a straight grain (parallel to the grainline) or a bias (45 degrees to the grainline) grain. Grouping these together will create fabric waste so keep them separate for maximum fabric utilization.

- Be aware that the Type of Fabric you use will play a vital role in fabric consumption. Plain and block printed fabrics will use less material than striped or checked fabrics whose matching parameters can lead to constraints

- The Shrinkage of the Fabric must be considered when calculating fabric consumption. Patterns must also be made with a shrinkage allowance for all materials that shrink.

- Thread Consumption must also be considered as an incorrect calculation could lead to excess ordering. Check out this guide for calculating thread consumption.

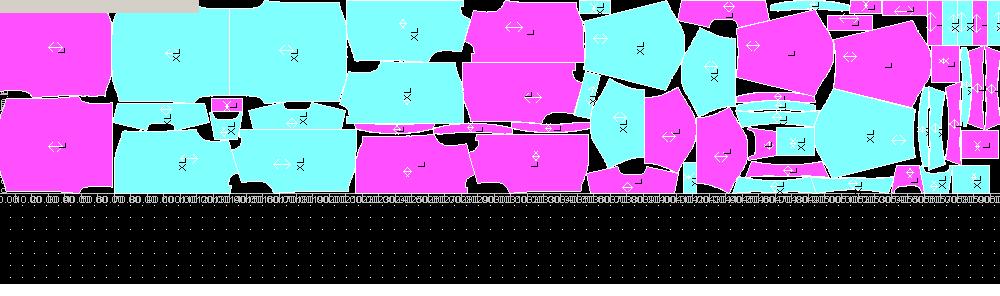

To get the most out of your material, Lay Plans and Markers are used in the industry.

What is Lay Plans when Cutting Fabric for Production?

Prior to making the jump to production, you will need to get your samples made. Cutting fabric for production and optimising fabric consumption is important at this stage even if you’re only producing one sample per style. It’s so easy to over-estimate fabric amounts and to be left with small pieces after your sample is done.

By creating a lay plan, either in-house or at a pattern grading company such as Gradeline will benefit you hugely. The lay plan is also useful to determine pre-production costings for the production of quantities larger than samples. Each size of a garment will have its own lay plan to simplify the calculation of fabric yield.

How to create your own lay plan?

When cutting fabric for production or even samples, you can easily create your own lay plan. For that you will need to know the width of the fabric you’ll be using for your samples. A sheet of pattern paper, the same width of the material is then placed on a table.

Your pattern is then laid over the paper and each piece is drawn onto the paper in such a way that ensures that there is a minimum amount of waste between each pattern piece.

Ensure that your grainline markings on your pattern pieces, are parallel to the straight grain of your fabric. This sheet can then be used to determine how many meters of cloth are required and should also be referred to when laying your pattern onto the cloth.

The Gradeline service (or other like grading providers) is similar to what you would produce in-house but they will give you a digitised file as well as A4 sheet with the lay plan printed on it.

What is a Production Marker?

Making the jump from small-scale pattern-production runs to 500 items per style can put a strain on your cash flow forecasts.

Factories that produce larger runs should suggest ways for minimizing unnecessary expenditure on fabric purchases while producing your garments more efficiently.

One suggestion should be that you use a Production Marker as this will solve the former and improve the latter.

A production marker is a computer-generated guide of your pattern pieces that is used to reduce fabric waste in the cutting process. A self-adhesive bond paper is used and all garment sizes are represented on the paper. The paper is laid on top of layers of fabric and each layer is called a ‘ply’. The amount of layers used is dependent on the fabric yield and quantities of garments being made.

You may think that the marker could be re-used but once it’s laid onto the fabric the cutter will use an electric cutting tool to cut through the paper and the layers of material. Therefore, it’s a single-use item and a new marker will have to be printed every time more garments have to be cut out. No two orders are typically the same so a previously used marker will be obsolete for a new order anyway.

However, it’s possible to get a digital copy of the marker file from the marker producer and to refer to it should you receive a duplicate order.

When you are cutting fabric for production and consider the savings you could make, it’s worth opting for the production of a marker.

In clothing manufacturing fabric, costs are in the region of 60-70% of production costs, so anything that can improve your fabric yield will invariably increase your profit margins.

The estimated savings of using a marker equates to 25-30% in a fabric. An example of a marker that cost £280 is one that allows a 6 size grade and which reflects the ratios of the most popular sizes. Complicated patterns, printed fabrics and expensive fabrics will increase the value of using the marker.

How are Patterns Laid out for Cutting on a Production Run?

When cutting fabric for production, the laying of patterns for production runs differs from that of samples.

When cutting for samples, the fabric will be placed on the cutting table on the fold. The patterns are then laid on top, drawn around and then cut out.

Manufactured production runs are usually produced in a factory with very large cutting tables. The fabric will be unfolded and laid flat to maximize the space. A lay plan will be referenced by the cutter in order to determine how the pattern should be positioned on the cloth. The production marker will then be used to prepare a marker ratio.

The number of layers of fabric that are spread onto the cutting table is determined by the size of the order and the thickness of the fabric.

Related reading: Fashion Pattern Cutting: From idea to pattern

When cutting fabric for production, fabric consumption can be determined by the type of markers that are used by the factory:

- Single size markers use more fabric

- Multi-size/two-way markers are the most commonly used and will optimize fabric usage

- Sectional Markers use a single size marker in one or two sections. Fabric consumption is more.

- One-way markers are used for striped or plaid fabrics and fabric consumption is high.

The process of creating samples and cutting fabric for production in apparel is so much more than simply laying your patterns onto a couple of meters of cloth.

The type, width and finish of your fabric will make an impact on how much of it you need to purchase.

If you have any questions about this article or general feedback then please do not hesitate to let us know in the comments below.