If you are a startup, it is always difficult to know where to start with regards to budget planning. Sample development is the foundation that decides the timeline and the cost of your end product.

Let’s find out how you can plan your sample development costs.

The idiom ‘How long is a piece of string’ comes to mind when we consider how much money start-up fashion-preneurs will need for sample development.

However sure you are about your design in regards to fabrication, fit and finish; extra costs will always be incurred during the sample developmental stage.

Any design changes and fit amends will incur additional costs than your original quote and any meetings with freelance makers to discuss these changes will also need to be worked into your costings.

It would be a wise move on your part to add a buffer for additional costs which could increase from anywhere between 25 -50%.

If your costs don’t increase then at least you have saved yourself some money. Should they increase then at least you have made an allowance for it.

Sample Development Stages

Sample development usually goes through a minimum of three stages and a maximum of 5.

You’ll need a prototype/toile, a 1st sample and a second one should any changes be required. Additional samples may be necessary should further development be required.

There are three approaches to consider when embarking on sample production:

- Working with a factory that offers a fully factored service whereby you send them a detailed Tech Pack with fabric swatches and trims. They will develop two sets of samples for you, an Initial Sample and a Pre-Production Sample.

- Should you choose to use a CMT (cut make and trim) unit you will need to provide a Specification sheet, pattern, materials and trims.

- Your third option is to use freelancers for each process, tech pack creator, pattern cutter and a cutter/machinist to sew your sample. The comprehensive list below will guide you in regards to the costs involved for each stage of sample development.

Sample Development Costs

Fashion Tech Pack

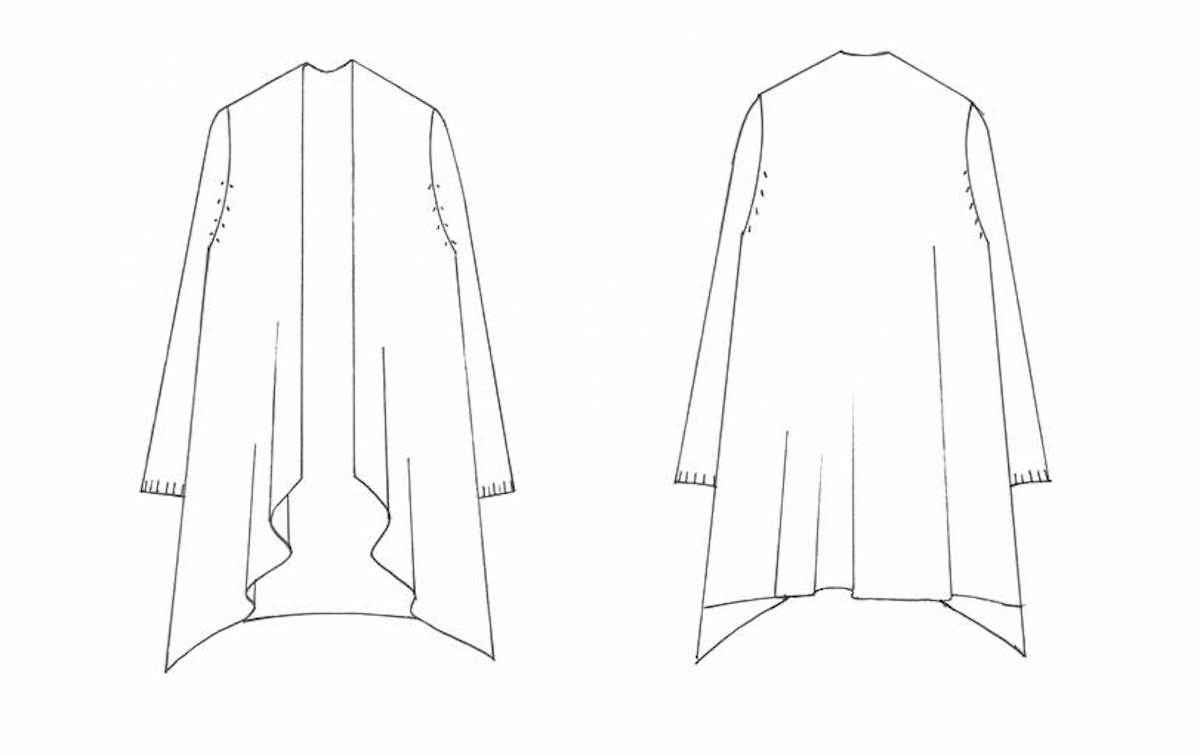

Your Tech Pack is the blueprint of your design, and as such needs to include more information than you think necessary.

It must contain all the necessary components required to create your sample as the provision of this important pack will enable the factory to develop an initial sample for your approval.

The type of information that it needs to include pertains to the fit of the item, with relevant measurements included such as, sleeve length, trouser or skirt length, the overall fit of the item whether it is loose or fitted.

Include the type of material you’d like to use, particularly whether it is a stretch fabric or woven. Also, include all trimmings details and lining preferences.

Cost to Make a Tech Pack

Tech pack production can be done by you if your technical drawing skills are up to scratch. Google “Tech Pack” on your computer for insights to developing your own. Create one by yourself or hire a fashion designer to help you with it.

Should you choose to use the services of a professional expect to pay anything in the region of $132 for a simple item or $330 upwards for something more intricate. Find a professional on People Per Hour.

Some factories will help you with it and make it for you as part of your sampling process. Ask your factory if they can and will do this for you.

Pattern Cutting

1. If you decide to use a CMT unit you will need to provide a pattern. In the first instance find a good pattern cutter who understands design.

If you have more money available, you could try to find one through an agency such as Freedom, Reed and Indeed.

2. Once you’ve selected one who specializes in your particular area speak to them about the type of materials that would be suitable for your range before you commit to purchasing that beautiful silk chiffon that’s totally unsuitable for a structured garment.

3. Your selected pattern cutter will base their rates on the complexity of the design, and the amount of detail you have provided in your Tech Pack if you have one.

Pattern cutters can develop patterns based on very simple drawings such as their ability to interpret other people’s ideas.

Should you, however, be in a position to provide detailed sketches with design lines, dart placements and front and back views then your final costs could be less.

4. Include as much information as you can especially the body measurements of your ideal customer, as that will enable the pattern cutter to render your design as close to your idea as possible.

The pattern cutter will estimate how much time will be needed to create the first pattern and toile.

For example, a simple A-line skirt with side pockets and a waistband should take 3 hours including the toile.

5. A fit meeting with the client should take 1 hour. If the item is perfect and doesn’t need any tweaking then the pattern will be checked over to ensure that all the relevant information is on it.

Your pattern and toile will then be delivered to you. Should the toile need further development, however, be aware that your costs will rise and will have to include time for further fit meetings?

Cost of a Pattern Cutter

A good pattern cutter will provide terms of service sheet with full details of how they work and the costs involved. Hourly rates are in the region of $25 – $50 + depending on their experience.

Materials and trims

1. Fabric and trimmings costs will be more expensive during the sampling stage as you’re not buying in bulk.

2. Try to avoid purchasing material from retail outlets as firstly, it will be expensive and secondly, retailers tend not to do wholesale. So, if you do eventually buy in bulk you won’t get a reduction.

3. Comparatively, retail prices per metre will be double and sometimes triple the wholesale costs. Try to source material directly from wholesalers as some companies will offer a tiered price structure depending on the amount of material you purchase.

Bennet Silks, an online supplier in the UK offer a tiered service for sales between 1–9M, 10-100M and 100M + with prices increasing by 20%.

Sample making

1. The fully factored route to sample creation is an all-inclusive service. Once you have sourced the right factory then you will need to supply them with your tech pack.

Providing it is detail-rich with fit references and measurements as well as fabric, trim choices and swatches, you should be in safe hands.

2. The factory will source your materials from their list of contacts or use supplies from their own stock.

3. They will also use their team of pattern cutters and sample machinists to create the Initial Sample.

Cost to Make Samples

The CMT route can be approached in two ways:

- You can work with an independent pattern cutter who will produce your initial pattern based on your sketch, toile and Specification sheet.

These items will then be presented to the CMT unit, along with your fabric, fastenings and trims. The unit will then make your item and charge an hourly rate of $26 – $40.

- The second approach is to use a unit that takes care of the pattern cutting and the sample but will expect you to provide fabrics and trims. Nailya at Plus Samples offers this service.

“We offer an in-house service comprising of a pattern cutter, cutters and machinists. It’s important during the development stage to work closely with the pattern cutting as it’s the first time our machinists will make the sample.

Should anything not work correctly it’s better for us to have the pattern maker close by to discuss problems. We charge $40 per hour to develop samples.”

Should you decide to use freelancers for every stage of the sample making process you will need to provide the machinist with materials, trims, a pattern and a fully functioning toile to work from.

If you’ve chosen a good machinist they in return will deliver a well-made sample. Expect to pay $20 – $33 per hour depending on the complexity of your product.

Top Tips

Do remember that sampling is much more expensive than production because the maker is producing a one-off item that they have never made before.

You, as the designer will also no doubt, change your mind about certain details once you have seen the first sample so remember to add your surcharge buffer of 25 – 50% to allow for these amendments. Once you have progressed from the sampling stage you will be charged a fixed price for production.

What has been your experience with sampling? What are the biggest costs associated with it? Share with us in the comments below.